Construction & Demolition Waste Plant

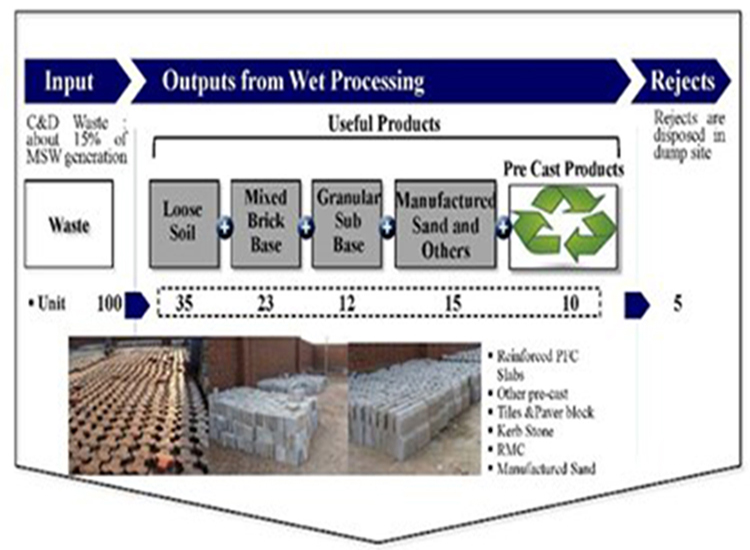

We Provide consultancy and turnkey services to Develop and Establish Construction and Demolition waste processing plant. A plant of 100 TPD capacity to process Construction and Demolition waste has been established by Indore Municipal Corporation under our consultancy and supervision. The C&D waste may become a great savior for available natural resources. Its effective management would surely provide a milestone step in environment friendly development framework in the country. For example, the river sand is primarily used for building and construction purpose, the increase in its demand almost double in last two decades impose adverse environment impact of sand mining. The manufactured sand from C&D waste or use of waste plastic in structural concrete can become a possible and sustainable alternative of sand.

Construction & Demolition (C&D) Waste, is one of the most challenging issues being faced by the rapidly developing country like India. C&D waste consists of waste that is generated during new construction, remodeling, renovation, repair and alteration of residential, commercial, government or institutional buildings, industrial, commercial facilities and demolition of buildings, roads, bridges, dams, tunnels, railways and airports. Often contain Concrete, Metals and plastics, Wood, Asphalt, Gypsum, Salvaged building components such as doors, windows and fixtures, Masonry, bricks and other miscellaneous. C&D debris often contains bulky, heavy materials that include:

- Concrete, wood, and asphalt (from roads and roofing shingles).

- Gypsum ( the main component of drywall).

- Metal, bricks, glass and plastics.

- Salvaged building components, such as doors, windows and plumbing fixtures

While C&D waste streams are large in volume, they generally contain relatively inert material, which are of low risk for waste management. It is commonly understood that this waste can be considered a resource, either for reuse in its original form. Due to increasing waste production and public concerns about the environment, it is desirable to recycle materials from building demolition. As per Rule 3 (c) "construction and demolition waste" means waste comprising of building materials, debris and rubble resulting from construction, re-modeling, repair and demolition of any civil structure. The rules shall apply to every waste resulting from construction, re-modeling, repair and demolition of any civil structure of individual or organization or authority who generates construction and demolition waste such as building materials, debris, rubble.

It is estimated that the construction industry in India generates about 10-12 million tons of C&D Waste annually. The presence of C&D Waste and other inert materials is significant (almost one third of total MSW on an average), but so far not much development has taken place for utilizing this in an organized manner. It constitutes about 20 % of the municipal solid waste (excluding large construction projects). Projections for building material requirement of the housing sector indicate a shortage of aggregates to the extent of about 55,000 million cum. Additional 750 million cum aggregates would be required for achieving the targets of the road sector. Recycling of aggregate material from construction and demolition waste may reduce the demand- supply gap in both these sectors.

Environment and Social Impacts of Unmanaged C&D Waste

To address the following problems of resource depletion, increasing demand for building materials, societal awareness on pollution effects (dust, pollution due to traffic congestion owing to roadside disposal) of C&D these rules were framed.

- Impose strain on landfill needs.

- Hazardous portion of waste, such as asbestos, could lead to potential harm to the environment and public health issues.

- Illegal dumping affecting the bio-habitat of dump area and creates potential public health issues such as mosquito breeding.

- Potential high value of recycled material not tapped and gets buried in landfills or illegal dumps leading to economic loss.

- Monitoring, Evaluation and AssessmenIncreasing quantity of C&D Waste leads to un-sustainable situation.

- Reliance on natural sources for material leads to escalating price, un- sustainable supply and high transportation costs.

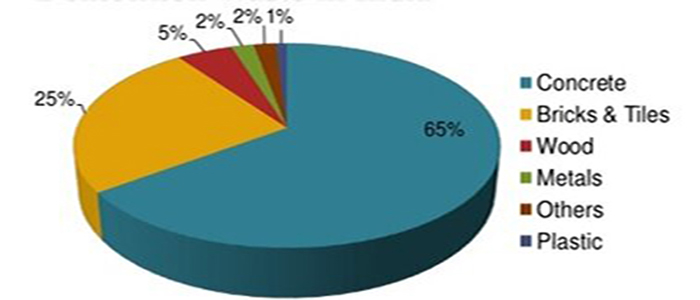

Composition of C&D Waste

The major/ minor components of the C&D waste are as follows:

- Cement concrete, Broken Cement plaster.

- Broken Bricks.

- Steel (from RCC, door/window frames, roofing support).

- Rubble, Broken Stone (marble, granite, sandstone).

- Broken Timber/wood (especially in the demolition of old buildings).

- Soil and Sand, Gravel, glazed tiles etc.

- Broken Conduits (iron, plastic), Broken Pipes (GI, iron, plastic).

- Broken Electrical fixtures (copper/aluminum wiring, wooden baton, Bakelite/ plastic switches, wire insulation).

- Broken Panels (wooden, laminated).

Advantages of C&D waste Management:

Economic advantage:

- Improvement of the income situation of the recycling industry.

- More jobs for workers with low qualification levels.

- Recovery of costs associated with transportation and tipping fees.

- Good quality of waste materials stimulated by better prices.

- Less wastes end up in landfills, increasing lifetime and reducing costs.

- Return of waste materials into the materials cycle.

- Reduction of the dependency on primary materials.

- Lower prices than new materials.

Environmental advantages

- Less primary resources, smaller raw materials warehouse, lower landscape consumption.

- Reduction of CO2-Emissions.

- Less production energy when recycling.

- Good quality of waste materials stimulated by better prices.Smaller transport distances.

- Recycling discourages illegal dumping and reduces negative environmental effects upon groundwater, surface-water, air, flora & fauna and landscape.

- Return of waste materials into the materials cycle.Controlled disposal of non-mineral C&D waste means to be able to prevent ignition and incineration of e.g. rubber and plastic.

Social and health advantages

- Reduction of proliferation of pests if C&D waste is deposited on controlled Sites.

- Emissions into the air or leaching of toxic substances into the soil and/or groundwater affect the population.

- Less production energy when recycling.Unstable dumps and deposits are dangerous for civilians and workers.

- Uncontrolled incineration of C&D waste can cause emissions of toxic compounds or substances such as dioxins.

- Lower growth rate of landfills and more space for productive uses.

Social and health advantages Construction & Demolition plant at Indore

Construction and demolition waste processing plant in Indore is setup by Indore Municipal Corporation under our consultancy and supervision. It is located at Devguradia Waste Processing plant in an area of 4 acre. Presently Indore generates about 60 TPD C&D waste. Looking into the project life of 15 years, the plant is designed with a capacity of 100 Tons per day (TPD). We, Eco Pro Environmental Services has been Project Design and Management consultant for the project and aslo the consultant for Indore Municipal Corporation.

To support the plant, IMC through its contractors uses all the products produced at the C&D plant at market price.

Four major products are made which are as follows:

- Paver block with Glossy finished surface.

- Curb stone.

- Rough paver block, paver plocks.

- Masonry brick and cement bricks.

- GSB and earth filling material.

We design the C&D plants compliant with MSW Rules and C&D waste management and handling rules 2016. Our plants C&D waste into aggregates, which in turn is converted to Ready Mix Concrete, cement bricks, hollow bricks, pavement blocks, kerb stones, concrete bricks and manufactured sand, thereby reducing the consumption of fresh stones and sand, and mitigating pollution arising in the process. Using Plant technology for Indian conditions, the C&D waste plant is able to recover about 95% of incoming C&D waste. We use 3Rs policy, use of waste minimizing technologies and reuse of materials is adopted to minimize C&D waste. Recycling of C&D waste by converting it to useful products offer dual benefit of saving landfill space and reduction in extraction of natural raw material for new construction activities, leading towards sustainable development.